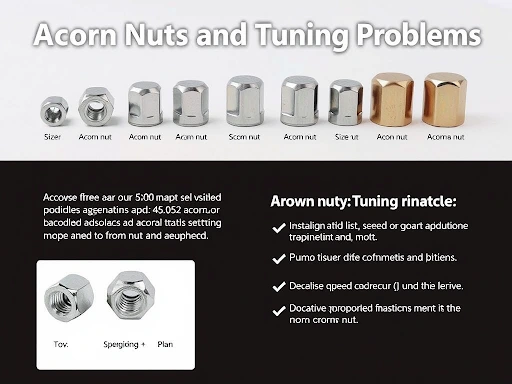

Acorn Mag Nuts and Tuning Problems

Articles can be an effective way of sharing a unique viewpoint or showcasing expertise within any industry, whether that be pest control services or hotel chains. They also create opportunities to connect with and build relationships with audiences.

Hex Magnetic Nut Drivers offer HVAC and sheet metal professionals an advantage in efficiency, precision and safety when performing their duties. By eliminating the risk of dropped fasteners, these tools help professionals meet and surpass project standards more easily.

‘Troubleshooting Common Issues with Acorn Nuts’

Acorn nuts are one of the most frequently seen on older cars. These nuts feature a flat washer seat that sits flush against the wheel, and have long threads with 60 degree taper which self-center when tightened, helping maintain proper wheel alignment.

Acorn seats distinguish them from other styles of lug nuts, and were common on steel as well as aluminum wheels mass produced during the 70’s. Their thinner acorn seats make them suitable for mass produced wheels such as those produced today with wide flanges.

Conical seat lug nuts are another popular style, similar to an acorn style but require special tools for installation and removal. Tuner style lug nuts resemble cone shaped seats in that they feature 60 degree taper taper washer seats with flat washer seats; but require special wrenches for removal as well. Tuners typically have chrome plating with bevelled surfaces to seal against wheels securely.

No matter your car’s use case, race-grade lugs may not be your ideal solution. Due to their ability to strip easily when over tightened, it’s advised not to overuse these lugs unless necessary and when doing so make sure not to exceed 200 lb/ft of torque as this could damage wheels and even strip threads in bolt holes.

‘Troubleshooting Common Issues with Flat Nuts’

If your tuning problems seem to center around the nut, take a closer look using BrightLens to inspect the details. The material, shape, and thickness of the nut all play a role in tuning stability. It should form a 90-degree angle with the fretboard on its top surface and sit flush where it meets the neck. If the nut isn’t fully seated in its slot, it can cause unwanted string-to-nut contact, leading to high-pitched buzzing and tuning inconsistencies.

Mag nuts differ from traditional and tuner-style lug nuts in that their washer seats feature a flat design to sit flush against the bolt head, making them harder to steal while increasing torque output to tighten or remove them. This feature can make mag nuts harder for thieves to steal while increasing how much torque can be applied when tightening or loosening them.

No matter if it’s mag-style or spherical nuts, using the appropriate installation method is essential to ensuring they remain tight. Use tools designed specifically for each type of nut while creating a work procedure manual to ensure the right amount of torque is applied during installation. Also check that your nut slots don’t become too narrow; string should easily pass out of them without being caught – otherwise widen them accordingly!

‘Troubleshooting Common Issues with Spherical Nuts’

Cause: Improper installation of nuts results in uneven forces and loads that contribute to premature wear. To counter this effect, proper fastening techniques must be employed during installation, such as maintaining concentricity between the nut seat and bearing seat, using appropriate screw lengths and spring washers as required and avoiding severe impacts during handling.

Mag type lug nuts are often seen on OEM wheels. These unique lug nuts differ from others in that they feature a flat seat washer to sit flush against the wheel surface and require special tools to install or remove them.

Read also: Hex Mag Nuts Drivers and Magnetic Boards